Students Use Solid Edge To Win Design Competitions – Part 2

<< Part 1

SkillsUSA 2010 was a Technical Drafting competition where Issac Wasilefsky, a student from Huntsville Center for Technology, won the first place. This is how Issac explained the competition:

“All contestants met in the morning for a design briefing where they were given copies of the problem. I will define the problem as an assembly in which we the contestants must design all required parts and assemble properly. What is included in the problem is specific critical dimensions, tolerances, GD&T, as well as material and manufacturing notes.

Once the competition started, everyone went to their computers to start modeling the problem. The contest is organized such that the judges require certain drawings to be turned in by a deadline. This means that each contestant is working on the same parts in the same order at the start of the competition. A little note about how the contestants are graded. Each contestant will turn in drawings specified in the problem. This makes up most of the grade. The judges look for proper application of drawing standards, appropriateness of dimensioning, proper notations on the drawing, in addition to the correct solution for each model.

During the lunch break there is usually a ECO for one of the parts so we will have to recalculate and modify the part per spec. For the final four or five hours, the judges stop answering questions about the problem in order to simulate the ‘customer leaving town.’

In all the competition lasts eight hours which includes a morning briefing as well as a lunch break. Normally there are several parts which make up an assembly. This years assembly was a seam saw to be used in the medical field. The competition tests practical knowledge of drafting, calculation using tables, ability to read part spec sheets, among the skills to follow instructions given as well as discerning important information given through descriptions

There were 40 contestants who participated. Generally each state holds its own competition and the winner at the state level moves on to the national competition.”

Issac used the student version of Solid Edge V20 in the competition. Here are a few screen shots of the model and drawings he created and his comments below them. Click the images for larger views.

“This is the entire seam saw assembly. If you noticed that the a lot of parts have errors displayed in the PathFinder, this is because they were generated using Standard Parts and the machine that I took the screen shot from does not have Standard Parts loaded.”

“This is the entire seam saw assembly. If you noticed that the a lot of parts have errors displayed in the PathFinder, this is because they were generated using Standard Parts and the machine that I took the screen shot from does not have Standard Parts loaded.”

“This is the lower blade guard. As you can see, I rely on my sketches heavily.”

“This is the lower blade guard. As you can see, I rely on my sketches heavily.”

“I have in part activated and am editing the upper part of the coupling assembly. We were given much leeway in this part of the competition since it was more for demonstration purposes rather than a graded part.”

“I have in part activated and am editing the upper part of the coupling assembly. We were given much leeway in this part of the competition since it was more for demonstration purposes rather than a graded part.”

“This is the second page of my seam saw assembly. The horizontal line going across the bottom of the page let me know approximately where the solid edge academic watermark started so I would not have anything covered up by it.”

“This is the second page of my seam saw assembly. The horizontal line going across the bottom of the page let me know approximately where the solid edge academic watermark started so I would not have anything covered up by it.”

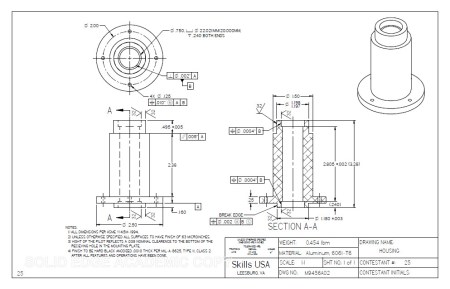

“I’m placing some GD&T in the housing drawing. After placing the symbols enough times, I memorized the symbol codes instead of using the buttons on the bottom of the dialog box. (eg. Typing in %DI for the diameter symbol)”

“I’m placing some GD&T in the housing drawing. After placing the symbols enough times, I memorized the symbol codes instead of using the buttons on the bottom of the dialog box. (eg. Typing in %DI for the diameter symbol)”

“Here I am updating the physical properties for the shaft model. This really helped when it came to the drawings since I had formatted a callout in the title block to automatically pull the weight from the model which saved me a lot of time not having to worry about it.”

“Here I am updating the physical properties for the shaft model. This really helped when it came to the drawings since I had formatted a callout in the title block to automatically pull the weight from the model which saved me a lot of time not having to worry about it.”

“My sketch for the revolved protrusion for the shaft. Once again I like using sketches with plenty of dimensions which makes it easier to go back and edit later.”

“My sketch for the revolved protrusion for the shaft. Once again I like using sketches with plenty of dimensions which makes it easier to go back and edit later.”

“The same thing as above for the housing. I prefer using revolved protrusions and sweeps where I can.”

“The same thing as above for the housing. I prefer using revolved protrusions and sweeps where I can.”

“The exploded seam saw assembly”

“The exploded seam saw assembly”

“This is the final seam saw assembly. I decided to do this drawing on two sheets in order to have plenty of room for the exploded assembly with the parts list. One of the stipulations that the judges had was to have the parts list in reverse order with designed parts listed first. On the first page the reference dimension was also a required part of this drawing.”

“This is the final seam saw assembly. I decided to do this drawing on two sheets in order to have plenty of room for the exploded assembly with the parts list. One of the stipulations that the judges had was to have the parts list in reverse order with designed parts listed first. On the first page the reference dimension was also a required part of this drawing.”

“This is the formed stand for the assembly. The judges allowed for the contestants to design it one of two ways: either as a formed piece as I did or as a weldment.”

“This is the formed stand for the assembly. The judges allowed for the contestants to design it one of two ways: either as a formed piece as I did or as a weldment.”

“This is the housing which sits atop the base and supports the upper part of the seam saw. A lot of this part was left to the contestants to figure out how it was to be properly designed. One of the few dimensions stipulated was the 2.805 dimension which demarks the distance between the two bearings. The finish and GD&T were specified in general terms in the problem description, but it was up to the contestants to properly place and apply the symbols and markings.”

“This is the housing which sits atop the base and supports the upper part of the seam saw. A lot of this part was left to the contestants to figure out how it was to be properly designed. One of the few dimensions stipulated was the 2.805 dimension which demarks the distance between the two bearings. The finish and GD&T were specified in general terms in the problem description, but it was up to the contestants to properly place and apply the symbols and markings.”

“This is the shaft that runs from the coupling up to the saw itself. Once again a good part of this part’s design was left up to the contestants. What the judges like to do with the problems is to give details about one part in the mating part’s description so the contestant has to be aware of what is happening with the assembly as a whole since a key dimension may be found in the mating part’s description.”

“This is the shaft that runs from the coupling up to the saw itself. Once again a good part of this part’s design was left up to the contestants. What the judges like to do with the problems is to give details about one part in the mating part’s description so the contestant has to be aware of what is happening with the assembly as a whole since a key dimension may be found in the mating part’s description.”

“This is the lower blade guard that sits on top of the housing. The .900 dimension comes from the requirement that only .100” of the blade is exposed.”

“This is the lower blade guard that sits on top of the housing. The .900 dimension comes from the requirement that only .100” of the blade is exposed.”

“This is the upper blade guard which sits above the lower blade guard. Together, the two blade guards were the fastest parts to model which was a real help since I was working right up to the end.”

“This is the upper blade guard which sits above the lower blade guard. Together, the two blade guards were the fastest parts to model which was a real help since I was working right up to the end.”

Part 3 >>