3D Printing At Discovery Charter School – Part 12

<< Part 11

By David Lewis

Back to the Lab: PLA, Precision & Mixed Media

Now that the first few weeks of the new school year are past and order has been re-established in the life of The Herd members, we are getting back to the lab. As a bonus The Herd has a spool of PLA to work with in addition to the ABS. Learning about the different properties of the PLA has been interesting for the group. One of the earliest findings is that when one “pulls” heated PLA, one can get a very long and fine thread unlike the ABS which snaps off much more quickly.

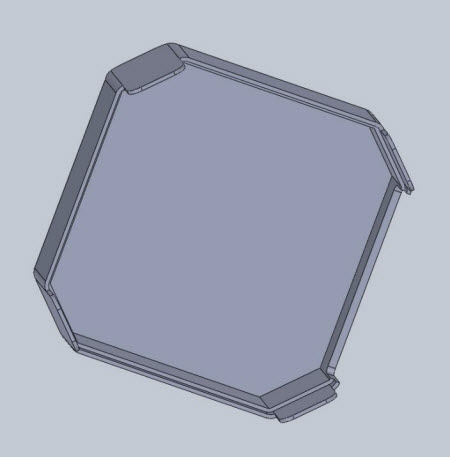

The Herd also found the PLA to have less tendency to warp and allows for an apparently “finer” build. One of the first projects with the PLA is an updated case for a gyroscope for a start up here in Silicon Valley. The case needed to have a port in the side allowing for the entry of the data cable in a different orientation.

Riley did the design in SolidWorks to the company specification.

And then build the first model of the prototype case. Note the inner ledge and setbacks the kids were able to achieve with the PLA.

The next challenge I gave them was to start working on some moving mechanical parts. As we were interested in improving the print quality of the Rapman, I had them find the “lashless” extruder drive gears that Chylld posted on Thingiverse and set up a “profile” on the Rapman to print them in the best resolution they could in ABS. The results are quite good and I expect that the new gears will give us even better printing resolution and finish.

An interesting side-effect of the gears is that when viewed edge-on, they appear to be thicker on one side than on the other. This inspired a lot of debate from The Herd until we pulled the calipers out and measured them. The gears are flat, but the chevrons create an optical illusion!

While Riley was working on the gears, Vernon was working on a mould to use for casing a silver/led mix. Our first attempt was ok, bout would have been better if we had used ABS for the mold and REMEMBERED to spray it with PAM before pouting the alloy.

For the ring itself, we simply used a scrap rain we made for the BusinessWeek Writer and pushed it into the alloy before it cooled.

Pretty Cool for the first day back in the lab since school started!

Part 13 >>