Thoughts On SpaceClaim Engineer 2015

Today morning SpaceClaim’s Director of Product Management Justin Hendrickson walked me though SpaceClaim 2015, the latest version of their flagship MCAD system that was made available to customers today (see press release). Justin made it a point to mention that things have gotten better for SpaceClaim, the product, since the company was acquired by ANSYS. The leadership remains the same and he tells me that ANSYS engineers have been brought on board to speed up SpaceClaim development. The core SpaceClaim team still continues to drive development decisions.

Like all good presentations, Justin’s had a couple of slides containing testimonials from large customers. Here is one of them that showed how SpaceClaim was used by 8000+ engineers at TE Connectivity to augment the 2,500+ Creo licenses used by CAD operators in the company.

I asked Justin if it was common for SpaceClaim to augment existing CAD licenses in a company instead of replacing them. He replied that SpaceClaim mostly augmented existing CAD licenses and replaced them only in instances where the existing MCAD system wasn’t deployed properly. The augmentation was common is large companies and replacement in smaller outfits. This probably explains why SpaceClaim has not and will not be the ruling the MCAD space any time soon. It is quite content being used as a secondary CAD system by engineers as opposed to traditional CAD operators. Hence the software is branded as “SpaceClaim Engineer” hoping to draw a distinction between engineers and CAD operators.

This slide sums up what’s new in SpaceClaim Engineer 2015.

At the top of the list is new tools for prepping models for 3D printing. It should be noted that these mesh modeling tools do not come as part of SpaceClaim Engineer and need to be purchased separately as an add-on. This makes sense as not everybody will want to mess with mesh models.

There are new tools to select edge loops, fill holes, repair models, push-pull facets and do stuff like smoothen facets, regularize them, thicken shells to give them volume, etc. There are also mesh analysis tools to measure mass properties, check wall thickness, etc.

Personally, I have a problem with software that claim to prep models for 3D printing. If we are talking about mesh editing features like the ones I just mentioned above then that’s just half the story. 3D printing is very different from 2D printing. In 2D printing you can be sure that just because a document prints fine on an inkjet printer, it will also print just as well on a laser printer. That’s not the case in 3D printing. The printability of a 3D model is dependent not just on the geometry, but also on the printer chosen, material used, printer settings selected, post processing done and a host of other parameters, which quite frankly, are way beyond the scope and experience of most CAD operator and engineers.

My point is these tools in SpaceClaim are only as good as the people who use them and the information they know. For example, in the image above, SpaceClaim Engineer has highlighted the parts of the model with thin walls in red, which is great. But what is an engineer going to do with this information if he doesn’t know which printer and material will be used to print the part. Unless he runs the 3D printer himself, there is very little he is going to get to decide about the way its going to be printed. In most cases, someone is going to look at the STL file in a service bureau and rework it anyways. And then there is this whole question of new materials showing up every now and then which throw all the previous calculations out of the window. All this makes the problem of prepping models for 3D printing very much a moving target.

Don’t get me wrong. I like these new mesh editing tools in SpaceClaim Engineer 2015. I just want to point out that a lot more needs to be thought through before the 3D model in a CAD system emerges as a part in a 3D printer. The rules of conventional manufacturing that engineers know all too well quite simply cannot be applied to 3D printing. This holds true for all CAD systems, not just SpaceClaim.

The following slide lists the enhancements in model prepping for analysis.

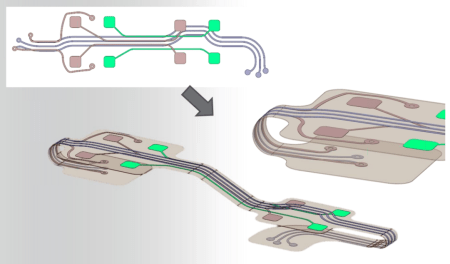

Working with large assemblies has been made easier by importing contents of layers into groups that can be selected individually. The link to ANSYS has been greatly improved to make it twenty times faster. New imprint and wrap tools have been added. Justin tells me that the wrap tool was developed in response to a customer’s desire to conduct analysis on electronic components. They needed a way to wrap 2D geometry over 3D parts as is shown in the image below.

If you look closely, you will see that some 2D elements flow over others. So this makes it a little different than the usual sheet metal problem which involves wrapping planar geometry over bend lines. To take care of this SpaceClaim has a way of offsetting the 2D elements so that they wrap around the 3D parts maintaining their position with respect to each other. I pointed out to Justin that doing something like this would mean altering the length of the items being wrapped. He confirmed my observation and noted that SpaceClaim adjusts the lengths accordingly so that the ends of the 2D elements always end up where they are supposed to after they are wrapped around the 3D object. I found that pretty neat, especially since you can unwrap the modified 2D elements and update the design so that parts fit when they are assembled for real.

Due to its ease of use SpaceClaim is widely used for concept modeling. Here is a slide that lists a few concept modeling enhancements.

Justin also showed me how easy it was to model using solids and meshes. He took an open mesh of a human face, gave it a thickness, created a solid block over the nose and cheeks, put in a few holes and did a boolean intersection to yield a partial mask of sorts.

Mesh models are not a dead end with SpaceClaim. You can push-pull sets of faces around at one go making it very easy to make quick changes when you don’t have the original solid model with you.

SpaceClaim uses feature angles to decide which faces are part of a particular feature, intelligently segregates the mesh into partitions and deals with them accordingly. This is more evident from the way SpaceClaim regularizes facets in a mesh in the example below. Regularizing is the act of altering the topology of a mesh so that the facets are better shaped instead of having long pointed facets.

Justin showed me a few other new features and enhancements as well. I have mentioned just those that I found interesting. I strongly recommend you visit www.spaceclaim.com to learn more about SpaceClaim Engineer 2015. A full list of new features can be found here.